"Bton's patented technologies enable the complete decarbonisation of concrete and sustainable construction."

Environmentally optimised and climate-positive concrete

co2-Negative

lightweight

USES LOCAL AGGREGATES

DIN/EN/GCC certified

Cost Efficient

scalable

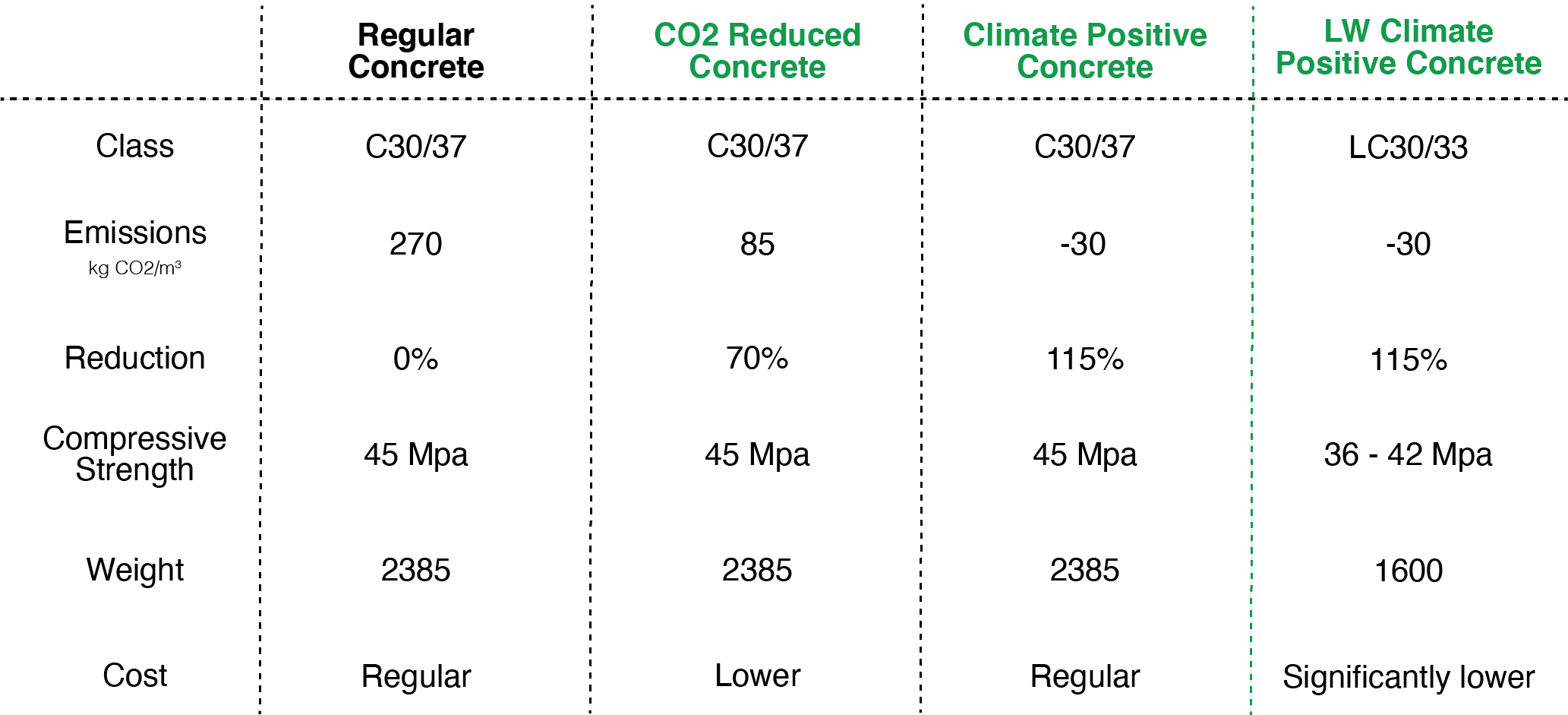

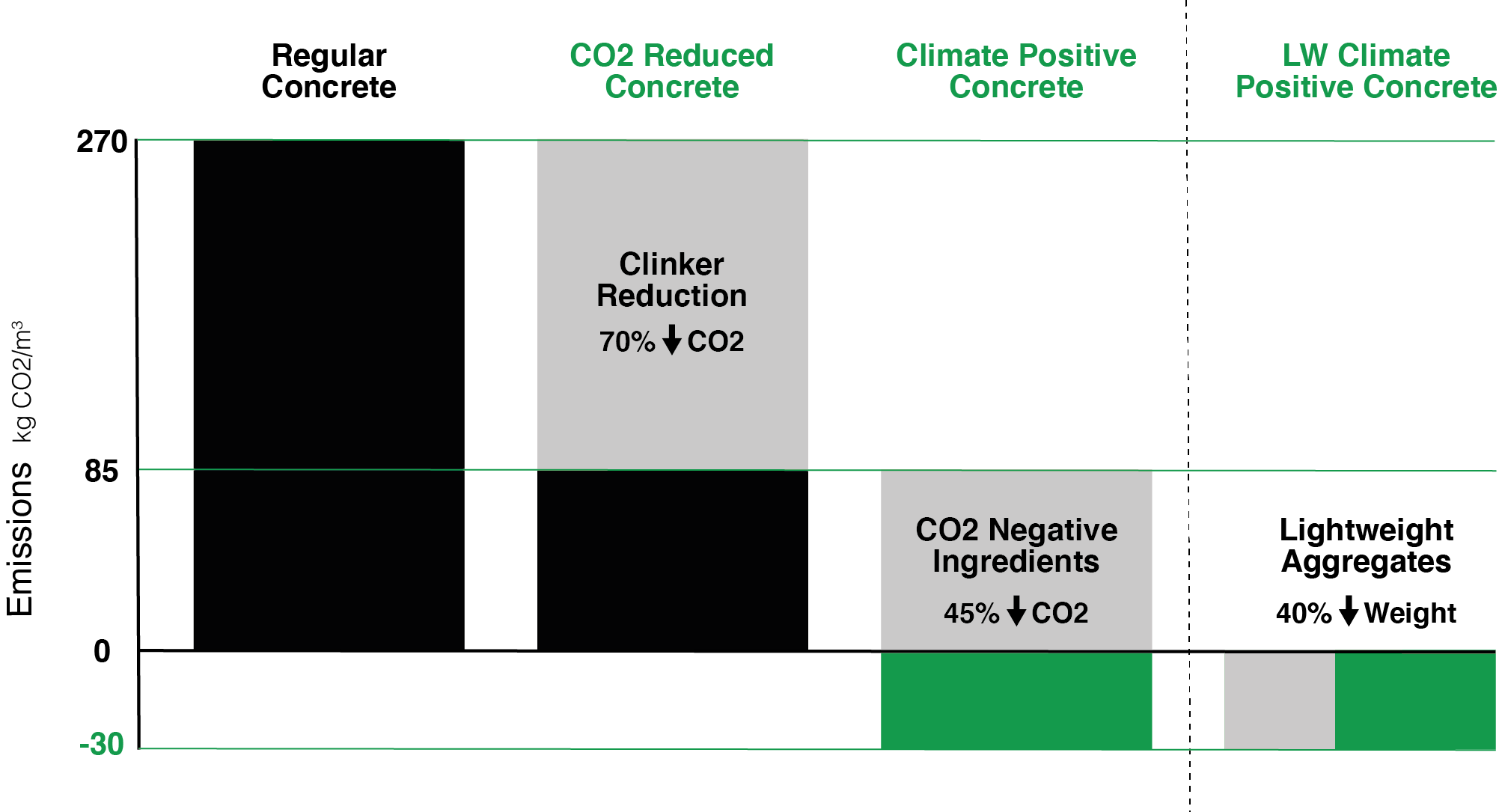

Bton in comparison with regular concrete

Decarbonisation Methods

Clinker and Cement Reduction

25%

The compressive strength is 25% higher compared with conventional production methods.

100%

The early strength is 100% higher than with conventional manufacturing processes.

CO2-Negative Ingredients

CO2-embedded

The mixing and processing technology allows greater volumes of CO2-sinking materials in concrete.

10% Less water

The mixing and processing technology requires 10% less water within production.

Lightweight and Local Aggregates

Bton can use locally available aggregates and optimise their CO2 and weight. Our concrete can, therefore, be up to 40% lighter and very favourably priced compared to the market, without any loss of strength.

40% Lighter

The weight can be reduced by 40% and the same compressive strength can be achieved.

Desert Sand

Bton's technology makes it possible to use previously unusable Desert Sand as well as regular sand.

Statically Active Fibres

The statically active fibres used by Bton can replace the need for steel in vertical concrete elements.

Lightweight

The use of statically effective fibres also reduces the weight.

CO2-saving

By replacing steel the use of statically effective fibres reduces the amount of CO2 in the concrete.